What is Broaching?

Broaching is a machining process that uses a toothed tool to remove material in a consistent and accurate way. There are two types of broaching services, linear and rotary, which are used to produce different kinds of machining finishes, but in either case, production broaching is typically only used for precision applications and high-quantity production.

What is a Broach?

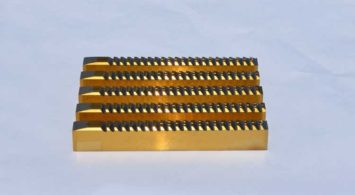

Broaching relies on a toothed tool called a broach. One of the most essential traits of a broach is the rise per tooth, which indicates the amount of material each tooth removes every pass. These teeth are then broken down into sections along the body of the tool: the roughing, semi-finishing and finishing sections.

Also, Broaches can typically be placed into two categories: (1) surface or (2) internal. Surface broaches comprise a variety of broach designs.

- Slab

- Slot

- Contour

- Pot

- Straddle

Internal broaches are another style of the broach. These also come in a variety of styles.

- Solid

- Shell

- Modular

- Keyway

- Concentricity

- Cut-and-recut

Regardless of the style of the broach, both surface and internal models are typically made from alloy steel or high-speed steel. If using high-speed steel, the bits are usually coated with TiN. Also, while cast iron is an exception, tungsten carbide is not used for the teeth of most broaches because it will not stand up to the use.

What is the Broaching Process?

The broaching process varies depending on whether surface or internal broaching is being used. Surface broaching is the most straightforward operation because one surface acts on the other. For example, either the broaching tool remains stationary, and the workpiece is moved against it, or the workpiece is stationary, and the broach is moved against it.

Internal broaching is not so simple. For the use of an internal broach, the workpiece must be secured in place with a work holder, which also acts as the mount for the broaching machine. Then, using the elevator on the machine, the broach is lowered into the workpiece. Then, the machine’s puller grabs ahold of the broach pilot, and then when the elevator releases the follower, the puller pulls the broach entirely through the piece. Finally, the workpiece is removed, and the broach reengages with the elevator.

What are the Uses of Broaching?

There are a plethora of uses for broaches. In fact, you have likely seen types of broaching in hand tools, appliances, plumbing, automotive design, farming equipment and a variety of other military and industrial applications. However, the primary use of broaching is in the production of high-volume parts that require accurate, repetitive and complex cuts. While the broaching process can be used for a variety of applications, the best materials to use are those with a hardness rating of between 26 and 28 Rockwell C. However, many production companies have seen success by using materials up to a hardness rating of 32 Rockwell C.

How to Care for Your Broaches?

When you receive a new broach, it is likely good for at least 8,000 cuts. However, if the broach is cared for and regularly sharpened, you can increase that original estimate to nearly 60,000 or more cuts. Broaches are expensive parts, with some costing roughly $2,000 or more, and while the estimated 8,000 cuts might be OK for smaller operations, not every company can afford to replace these tools so frequently. Therefore, after cutting 3,000 parts, it might be worth sending your broaches out to be sharpened and reconditioned to prolong the broaches usefulness and reduce overall production costs. If you have noticed that there is an increase in force required to cut your parts, then your broach may need some sharpening.

Contact Miller Broach

Contact Miller Broach, a broach company specializing in a variety of broach services, by calling 1-810-277-9857 or filling out our online contact form.